معلومات عنا

حقوق الطبع والنشر © 2024 Desertcart Holdings Limited

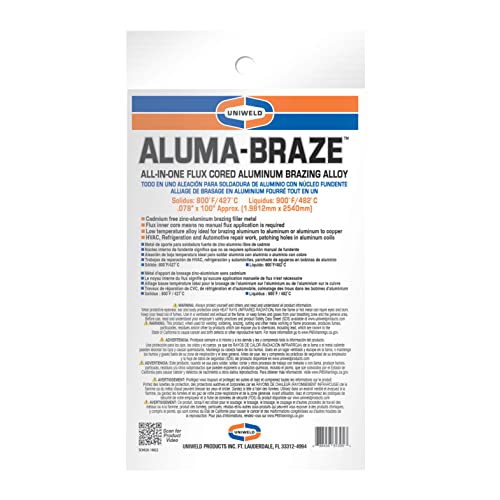

🛠️ Master the art of metal fusion with zero fuss!

Uniweld UAB Aluma-Braze™ is a premium all-in-one flux-core aluminum brazing alloy designed for low-temperature, cadmium-free joining of aluminum to aluminum or copper. Ideal for HVAC and refrigeration repairs, it eliminates the need for separate flux application, ensuring efficient, clean, and reliable metal bonding.

| ASIN | B0BLHW8SW4 |

| Are Batteries Included | No |

| Brand | Uniweld |

| Customer Reviews | 4.6 4.6 out of 5 stars (133) |

| Date First Available | June 23, 2023 |

| Included Components | フラックス入りアルミろう付け合金。 |

| Item Weight | 31.8 g |

| Material | アルミニウム |

| Model Number | UAB |

| Product Dimensions | 254 x 0.2 x 0.2 cm; 31.75 g |

| Quantity | 1 |

C**5

Works well and is easy to use.

M**S

Une correctamente el cobre con el aluminio no se batalla al soldar como con otras soldaduras

Q**5

This stuff works amazing. I can't believe how easily the flow started. The bond was strong as anything, no leaks. Copper to aluminum. Just spend your time cleaning the joint, especially the surfaces to mate. This is a low-temp brazing solder, too. So you can literally use a butane torch or a 60-watt soldering iron to get this to flow. I'm not saying that will get your joint hot enough, but this is a low-temp solder. Flows easy. Durable joints the very first time. Couldn't have asked for more.

K**E

I used this Brazing Alloy to repair a refrigerator that had a pinhole leak where the copper piping met the aluminum coil. I had my doubts on if this would work as brazing copper to aluminum is difficult and prone to leaks which is why my fridge leaked in the first place. The refrigerator company saved .2 cents by using aluminum tubing and told me my fridge was junk after only 3 years and not reparable. Instead of throwing it into the land fill i gave this brazing wire a try and what do you know it fixed the leak. It wasn't very difficult to use just a little pricey. However it saved a refrigerator from the landfill so i would say it was worth every penny.

J**N

As part of a retrofit job, I used this brazing rod to add a #10 nut to a used and very old R12 automotive AC line. I'm not sure if brazing rod was the best choice but I decided on it because I know it's a stronger bond compared to the lower temp aluminum soldering rods. Plus this rod has a flux core which seems to be very important for capillary action. I would have just tig welded it but I read that tig welding old R12 lines is problematic and results in having pin holes. Not sure if that's true but I didn't want to chance it. Some areas of the joint look a bit bumpy/porous, not sure if that's normal since this is the first time I've done this. I pressure tested it and found no leaks. I'm not able to test it at operating pressure since this is the high side line but I expect it'll be fine. I'll do an update once I get the system operating.

ترست بايلوت

منذ شهرين

منذ أسبوع